❤️🔥 HILOS at Milan Design Week 2024

Highlights from our Alcova exhibit at Milan Design Week (April 16-21)

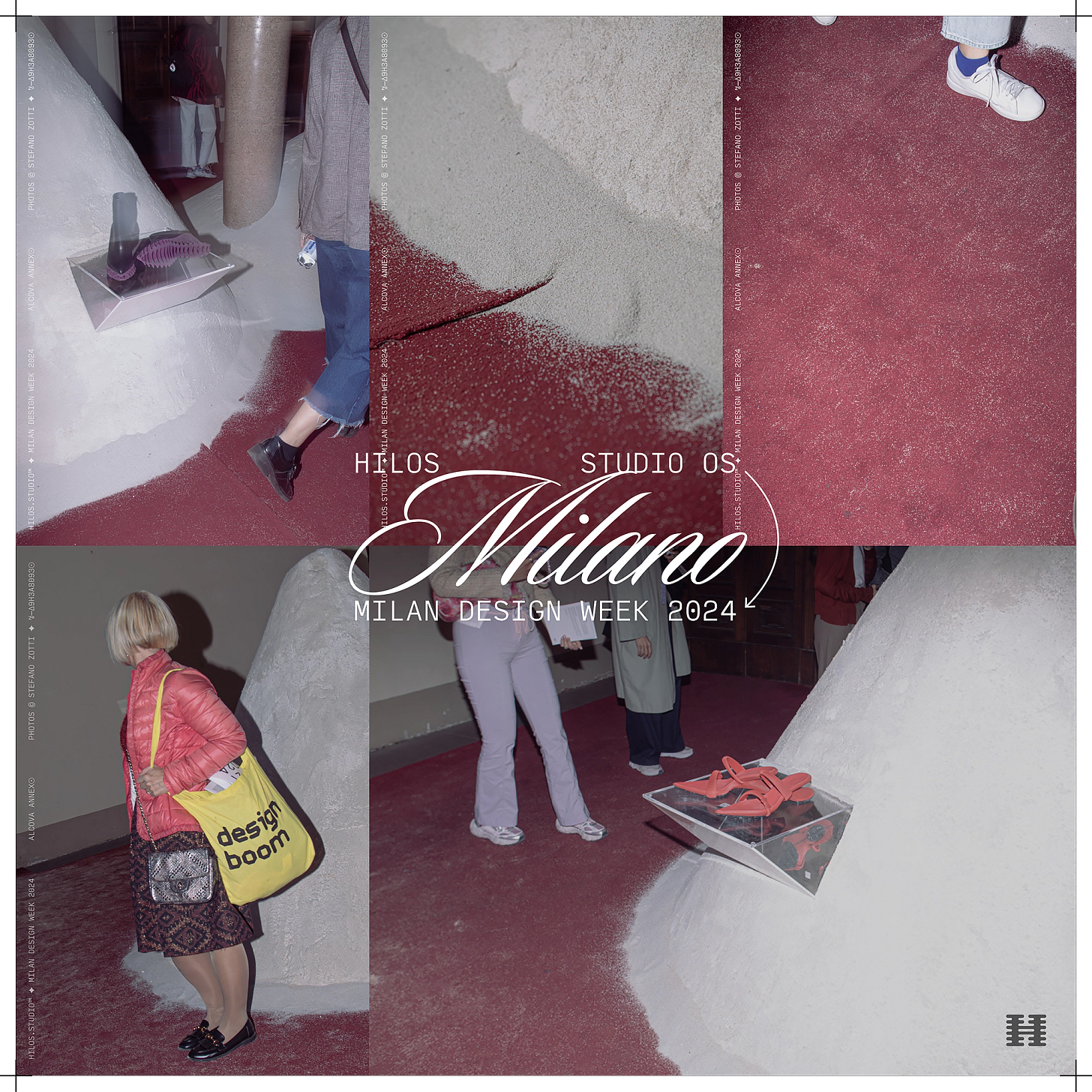

Hosted by ALCOVA1 at the Villa Bagatti Valsecchi2 for Milan Design Week 2024, we transformed a wing of this historic villa into an exhibition space that showcased a new collection of wearables produced under Studio, our innovation lighthouse where ideas are brought to life with brands that exemplify the future of craft.

The Exhibit

“It’s an Italian villa! We need more romance.” said Lillian Hardy, our art director. With Cooper Gill at the helm along with versostudio and the rest of our amazing team3, a freewheeling effort was made to design an experience that read like a love letter from earth.

Shoes emerged from dunes as a nod to volcanology and Fire of Love. A double arch colonnade bifurcated the room, with the back-of-house inspiring technical curiosity through various touchscreens and touchpoints. Attendees were encouraged to play with objects and materials and test drive Studio OS for the first time.

Our Vision: Born from Powder

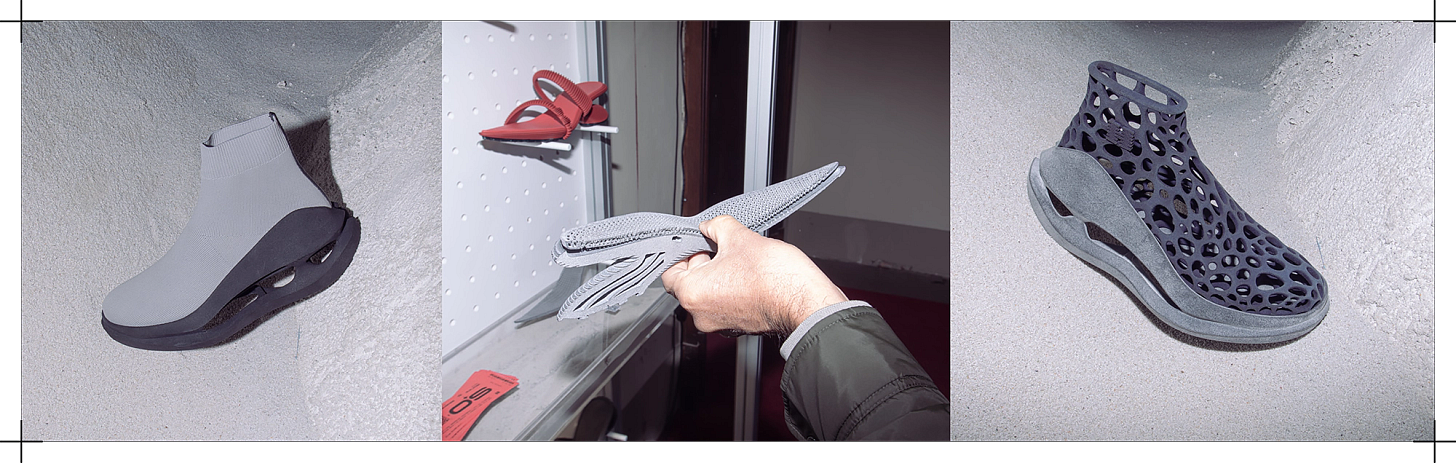

A thin layer of powder4 is spread across the bed, selectively sintered with hot light. This process repeats itself layer by layer, thousands of layers at a time, tuned at the voxel level, until a recognizable form emerges from the dust. Like a buried artifact, the printed object is excavated from TPU powder and thoroughly cleaned in preparation for finishing and assembly. This method of 3D printing is called Powder Bed Fusion, and it’s a mesmerizing process. Christy Lai, who leads software at HILOS, calls this powder “shoes in the raw”.

To juxtapose: have you ever seen an active volcano throw pyroclastic ash into the air? This fallen ash, or tephra deposit, is the raw material of creation. It’s a journey from the center of the earth to the liberated surface as additive poetics of form. Our landscape has been printing 24/7 since the beginning of time, and with it, co-authoring every chapter of the human condition onto geologic record. We too, are printed from these particles, or as Carl Sagan would say: cooked in the hearts of stars. The volcano is earth’s original 3D printer.

The dunes embody the analog of modern creation, and our mission was to spark a dialogue using the material that connects us to Earth and to each other. It’s still awe-inspiring to imagine that a pile of sand or TPU powder could somehow transform into your favorite wine glass or 3D-printed sneaker. While nature is a true inventor, it takes human ingenuity to invent the tools that transform these primitives into wearable art, and human responsibility to ensure our methods are sustainable for a greener future. And this is where Studio OS comes in.

Hello, Studio OS

During our time in Milan, we unveiled a new product creation tool to the public. Studio OS is the first generative design software to leverage AI models trained on 3D footwear, turning concepts into wearable realities with uncompromising speed, flexibility, and control.

James Carnes Product Tour at MDW

ABOUT JAMES James Carnes is an Innovator, Brand Strategist, and Executive. In his 25+ years in the industry, he has launched concepts like Boost, Primeknit, and Futurecraft, and led adidas sustainability strategy for many years. James was born and raised near Detroit, Michigan.

Alcova Panel: The designer, the algorithm, the crowd

On April 16, HILOS hosted a panel at Alcova featuring several giants of European design and architecture: Carlo Ratti (MIT professor and current organizer of the Venice Biennale), Arturo Tedeschi (acclaimed author and architect), Karin Peterson (Design and Crafts at the University of Gothenberg), and

MARGINALIA

ALCOVA →

Each year during the world's largest design event, Milan Design Week, ALCOVA brings together the people defining design culture today through groundbreaking work on living environments, products, systems, materials and technological innovation.

This historic villa, situated in Varedo, stands as a testament to the Bagatti family’s legacy, tracing back to the 16th century with Pasino de Bagatis securing land through a contract in 1530. As the main venue for ALCOVA, Villa Bagatti Valsecchi offers visitors a unique opportunity to immerse themselves in a space where history and innovation converge, underscored by its accessibility from Milan and its integration into the wider narrative of design and cultural development.

Big thanks to: Cooper Gill, Sean Coggins, versostudio, Andrea Galanti, Richard Ceccanti, Elias Stahl, Lillian Hardy, Christy Lai, Ty DeHaven, James Carnes, Mikele Schnitman

TPU, or Thermoplastic Polyurethane Powder, is a multi-purpose material with a rubber-like elasticity used for 3D printing. Printed product is fully recyclable, and each print run uses at least 80% reclaimed powder, creating less waste in every production.